PENETRON – Protection against corrosion of reinforcement steel

Corrosion of reinforcement steel is the main reason for concrete deterioration and a worldwide problem. Failure of concrete structures due to corrosion poses major safety implications for critical infrastructure such as highways, tunnels,bridges and other projects exposed to aggressive environments. The National Association of Corrosion Engineers (NACE) in the USA estimates the annual direct cost of corrosion for highway bridges alone to be USD 13.6 billion.

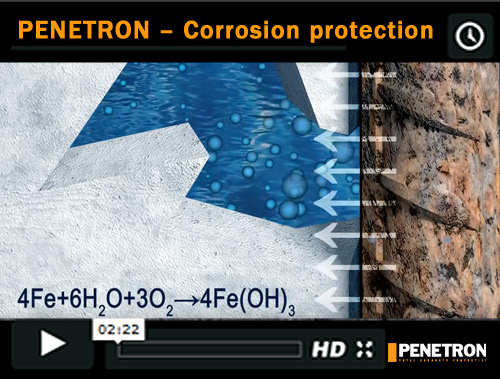

Steel is not a naturally occurring material (rather smelted and refined iron ore) and therefore it is subject to corrosion. As a thermodynamically unstable metal under normal atmospheric conditions, steel will release energy and revert back into its natural state – iron oxide, or rust. The buildup of rust increases the volume of the embedded steel element. This increase in volume exerts an expansive pressure on the surrounding cement paste causing cracking, delamination and spalling of the concrete. The resulting damage affects both concrete durability and service life.

Naturally, steel is protected against corrosion in the alkaline environment of concrete (pH 12 to 13) by a thin oxide layer, which passivates the metal. This layer prevents metal atoms from being dissolved and reduces the corrosion rate to insignificant levels. The corrosion of steel in concrete begins when the oxide layer is destroyed. The destruction of the passivating layer is caused by either an increase of the chloride concentration or the reduction of the pH level (reduction of alkalinity) in concrete.

Chloride ion penetration into concrete is the primary and most well documented cause for the corrosion of steel reinforcement. Water soluble chloride ions contained in seawater and deicing salts enter concrete through capillaries and microcracks. Upon reaching the reinforcement steel chlorides start penetrating the passivating oxide layer. Once a certain chloride concentration (threshold value) on the surface of the reinforcement steel is exceeded, corrosion is initiated as long as oxygen and water are present. Generally, in European countries and North America a tolerable chloride content is limited to or around 0.4% by weight of cement.

Carbonation progressively reduces the pH level of concrete. Carbon dioxide (CO2) in the air or water penetrates the concrete and reacts with hydroxides to form carbonates, which will turn into calcium carbonate (CaCO3) when reacting with calcium hydroxide (Ca(OH)2). This reaction reduces the pH of the pore solution. In total, carbonation can reduce the pH to about 7. When the pH of concrete falls below a value of about 9, corrosion of the steel reinforcement is initiated since it is no longer passivated.

The carbonation process requires water inside the concrete for the carbon dioxide to dissolve and to form carbonic acid (H2CO3). If the concrete is too dry (RH <40%), the carbon dioxide cannot dissolve, and carbonation cannot take place.

Concrete carbonation is a slow process that occurs over time and typically is not a concern for concretes with a design life of under 50 years. It nevertheless remains a major concern since carbonation is accelerated in more permeable concrete (higher w/c ratio, low cement content, low strength). In addition, most infrastructure and other critical projects are now designed with a service life of 100 years or more and many projects are built in locations with decreasing air quality (higher CO2 values).

Penetron protects concrete against corrosion of the reinforcement steel in multiple ways.

- Penetron is a highly alkaline material that helps to maintain the alkaline environment in which steel stays passivated

- Penetron reduces concrete permeability by forming insoluble crystals, sealing microcracks, pores and capillaries even under high, hydrostatic pressure. By keeping water out of the concrete, water-soluble chlorides are prevented from entering and initiating corrosion

- Water that is needed for dissolving carbon dioxide to form carbonic acid is prevented from penetrating into Penetron-treated concrete; significantly slowing down the carbonation of concrete structures

- Carbon dioxide gas diffusion is greatly reduced due to low permeability of Penetron-treated concrete

- Penetron self-heals new cracks throughout the service life, preventing water, which is required for chloride penetration and carbonation, from finding new ways into concrete

The diffusion of chlorides and carbonation through concrete is drastically reduced in Penetron-treated concrete. This results in a considerable delay in the corrosion of the reinforcement steel and therefore an increase in concrete durability. Independent studies have shown that this enhancement in durability can add 60 years or more of service life to concrete structures in critical environments.