| |

Dear Reader,

We are aware that this update reaches you in a time of great anxiety and uncertainty. And while business might not be the first thing on everybody’s mind right now, perhaps this edition of the PENETRON Newsletter will help restore some “normality” again and take our minds off the headlines in the news for a little while.

This edition focuses on repairing defects embedded deeply in a concrete structure. These defects can be effectively treated with PENETRON INJECT and the PENETRON System of crystalline products.

PENETRON solutions are employed in over one-hundred countries worldwide and our Newsletter gives you a closer look at some of our projects in the PENETRON Worldwide section below.

May this edition of the PENETRON Newsletter provide some well-needed distraction to our readers and, hopefully, we will see you in person again very soon.

Until then, stay safe, stay healthy, stay strong.

Jozef Van Beeck

Director, International Sales and Marketing

Penetron International

|

| |

|

| |

PENETRON INJECT – Restoring structural integrity and durability |

|

| |

HEPP Djerdap 1 Hydroelectric Power Plant, Serbia |

|

| |

Izvor Station, Bucharest Metro, Bucharest, Romania |

|

| |

Sofia Metro, Sofia, Bulgaria |

|

| |

La Palma, Riyadh, Saudi Arabia |

|

| |

PPP Project I, Comprehensive Underground Pipe Corridor, Xi’an, China |

|

| |

The Riverside New Town, Ankang, Shaanxi, China |

|

| |

National War Memorial, Delhi, India |

|

| |

Park Avenue Tunnel, New York, USA |

|

| |

|

|

|

|

|

|

|

| |

|

PENETRON INJECT – Restoring structural integrity and durability |

|

Repairing concrete defects is a common activity on construction sites. Concrete defects, especially those embedded deeper inside the structure (honeycombs, voids, structural cracks, etc.), will – over time – compromise the impermeability, durability and service life of concrete. Therefore, it is crucial to prevent these issues in the first place or properly address them when they occur. Very often, these defects are detected when the structure is already in use – requiring a repair solution that is applied from the negative side.

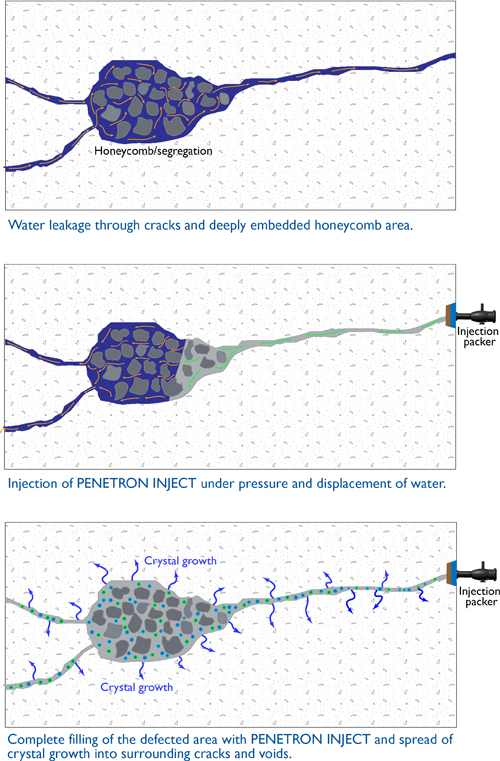

In this context, the option of injecting PENETRON’s renowned and proven crystalline technology into concrete to eliminate water leaks resulting from honeycombs, voids and cracks in the structure, is an effective and permanent solution.

PENETRON INJECT, is a highly effective, two-component, crystalline injection grout to seal cracks and fissures by filling hollow spots and voids in the concrete. The extremely fine particle size of the ingredients (for a very low, water-like viscosity) allows PENETRON INJECT to penetrate even fine hairline cracks in concrete and rock fissures and seal them.

Injected under pressure deep into the concrete, PENETRON INJECT displaces any existing water, filling voids with a crystalline micro-cement and immediately providing stability and strength to the repaired area. From here, the PENETRON crystal growth continues in the presence of moisture, as these areas usually contain a lot of water or moisture. Any remaining voids are sealed, stopping the flow of water.

Click on the image to enlarge

PENETRON INJECT restores the structural integrity of the repaired area and, unlike conventional injection materials like polyurethane and epoxy grouts, does not debond, crack and potentially allow water to leak through again.

The unique self-healing abilities of PENETRON INJECT ensure that any potential passageway for water in the defective patch is sealed. Preventing water from entering the concrete improves corrosion protection of the reinforcement steel, enhances durability and ultimately extends the service life of the structure.

In combination with our world-class PENETRON repair system (PENETRON, PENECRETE MORTAR, PENEPLUG), PENETRON INJECT provides a total solution designed to tackle even the most complicated repair situations.

For more information on PENETRON INJECT and PENETRON topical and repair solutions, please click here.

|

|

| |

|

HEPP Djerdap 1 Hydroelectric Power Plant, Serbia |

|

Djerdap 1 (Iron Gate I) Hydroelectric Power Station is the largest dam on the Danube River, located in the Iron Gate Gorge on the Serbia-Romania border. At the time of its inauguration in 1972, the dam was the 10th largest hydroelectric power station in the world.

The facility is jointly operated by Serbia and Romania and has a total output of 10.89 TWh (5.24 TWh on the Serbian side and 5.65 TWh on the Romanian side) based on its generating equipment.

In 2008, renovation began on the 36-year old concrete structure on the Serbian side of the dam. After the failure of previously applied repair solutions, Penetron Hellas was invited to present the PENETRON System in early 2019. The product demonstrations showed that PENETRON INJECT could successfully solve issues of deeply embedded voids and honeycombs. Shortly thereafter, the PENETRON solution was approved for the project.

PENETRON INJECT injection points

Subsequently, PENETRON was applied to several concrete elements and sections on the project, including the facility building, retaining walls, slabs, ceilings and columns. Several thousand square meters of concrete surface were treated with a PENETRON coating to seal the structure against further water ingress and prevent further deterioration.

PENEPLUG, PENECRETE and PENETRON slurry were applied to complete repairs on the water reservoirs and construction joints to permanently seal cracks and other concrete defects.

Thanks to the effectiveness of Penetron’s concrete repair and protection solution, the Iron Gate I project management team continues to rely on PENETRON for the ongoing repair works at the Danube River’s largest hydroelectric power station.

PENETRON-Team on site

|

| |

|

Izvor Station, Bucharest Metro, Bucharest, Romania |

|

The Izvor Station on the M1 (Yellow) and M3 (Red) lines of the Bucharest Metro is in the middle of the city: close to the Palace of Parliament, Bucharest Veterinary University, Gheorghe Lazar High School and Cismigiu Gardens. The station is part of the first Bucharest Metro line built in what was once the Izvor neighborhood on the right bank of the Dambovita River.

Being a shallow construction, Izvor station does not feature a vestibule. Instead, all ticketing machines are located on the track level, positioned centrally in the station. The south- and northbound platforms are connected by a single passage that runs beneath the tracks.

Opened on November 19, 1979, Izvor station was in operation for 35 years when water leaking through some of the construction joints in the tunnel section increased noticeably during rainy days. The situation became so severe that repairs were scheduled.

Despite the application of conventional repair materials, the construction joints continued to leak. Finally, a solution using PENETRON INJECT was accepted to seal all voids in the construction joint areas and stop all water flow into the tunnel.

The renovation work included opening and cleaning all treated joints. As a next step, holes were drilled into the joint to insert injection hoses. All surrounding areas were repaired with PENEPLUG, a fast-setting, crystalline repair compound. PENETRON INJECT was then injected under pressure into the concrete. Once PENETRON INJECT had set, all injection points were sealed, and the joint surface was covered with two coats of PENETRON.

Despite the challenging underground environment at Izvor station, all leaks into the tunnel were permanently stopped.

|

| |

|

Sofia Metro, Sofia, Bulgaria |

|

Sofia Metro in the Bulgarian capital opened in January 1998. In 2016, the metro was extended to comprise two interconnected lines serving 35 stations with a total length of about 40 kilometers (24.9 miles).

When leaks were noticed in one of the Metro’s underground parking garages, they contacted Penetron for a solution. Working together with MBRACE, the project contractor, Penetron Hellas applied a crystalline repair solution that included PENETRON INJECT, PENEPLUG and PENETRON to seal leaks in the cracks and joints of the concrete. The project was successfully completed, eliminating any water penetration into the underground garage.

|

| |

|

La Palma, Riyadh, Saudi Arabia |

|

La Palma Riyadh is a new, secure and fully furnished 480-unit, luxury residential community, finished in a contemporary western design from the ground up, including residential security measures.

With the intended residents coming mostly from the western expatriate community of Riyadh, a variety of housing options, recreational amenities, services and restaurants were designed as part of the community.

Waterproofing is an important part of protecting and maintaining the integrity of concrete buildings. The La Palma Riyadh project engineers specified PENETRON ADMIX and PENECRETE MORTAR for 14,200 m3 of concrete for its raft foundations, water tanks and swimming pools. Thanks to the effectiveness of PENETRON crystalline technology, the below-grade concrete structures at La Palma are now waterproofed and substantially more durable.

|

| |

|

PPP Project I, Comprehensive Underground Pipe Corridor, Xi’an, China |

|

The ‘Comprehensive Underground Pipe Corridor’ on Kunming Road in Xi’an runs from the east bank of Zao River in the west and extends to Xi’an’s’ Second Ring Road in the east. The corridor has a total length of 3,757m, of which 3,550m is housed in a two-floor pipe corridor with a section width of 12m × 10.9m, with -207m as a single-layer rainwater culvert with a cross-section of 11.6m × 5.0m. The upper level is a rainwater culvert, and the lower level is a large pipe gallery. The Pipe Corridor passes through three subway stations and crosses seven subway channels under a railway bridge; the corridor has a total of 136 exits.

The design of the Pipe Corridor combines several aspects of road infrastructure, including drainages and various pipe channels for easy access and flexibility for maintenance.

The design strictly followed the "Waterproof Technical Specifications for Underground Engineering" (GB50108-2008) standard, which calls for Level 1 waterproofing protection, a concrete impermeability level of P10 and a 100-year design life.

Parts of the corridor are below groundwater level (-4.7m to -16m) and all concrete elements on this project are directly exposed to water. This situation required comprehensive protection against water penetration and subsequent deterioration. The waterproofing solution also included the upper-level rainwater culvert, as well as the lower-level pipe gallery (slab and retaining walls).

After an expert evaluation, PENETRON ADMIX was specified as the waterproofing solution to ensure a completely waterproof concrete structure with improved durability and a 100-year service life.

PENETRON ADMIX was added to the concrete mix used in the concrete slabs and retaining walls of this giant project.

|

| |

|

The Riverside New Town, Ankang, Shaanxi, China |

|

The Riverside New Town, also known as the “New Huangpu” of Ankang, is a large residential complex built on the banks of the Hanjiang River in Ankang City in Shaanxi Province. The total construction area of this development was 123,356 m2, with a two-level underground garage (30,212 m2).

Since the project is close to the Hanjiang River, it required an effective concrete waterproofing solution for the basement structure to prevent water leakage and ensure overall concrete durability.

PENETRON ADMIX was used to successfully treat the concrete in the entire below-grade structure of The Riverside New Town residential complex.

|

| |

|

National War Memorial, Delhi, India |

|

This National War Memorial was built in 2018-19 by the Indian Government to honor the Indian Armed Forces. It was designed by Yogesh Chandrahasan and WeBe Design Lab and sits on an impressive 40 acres near the India Gate in the heart of Delhi, India’s capital city. The design of the memorial includes four concentric circles (Circle of Immortality, Circle of Bravery, Circle of Sacrifice, Circle of Protection) surrounding an obelisk with the eternal flame.?

The memorial walls incorporate the names of Indian armed forces personnel killed during the country’s conflicts and military operations since the country’s independence in 1947.?

The National War Memorial houses large below-ground tanks for water collection and storage. The tanks and the fountains, the monument podium and other water bodies required an effective waterproofing solution.

After detailed discussions with the project consultants, the originally-specified APP membrane was replaced with a Penetron crystalline solution to topically treat approximately 50,000 m2 of concrete surfaces with a combination of PENETRON, PENETRON PLUS and PENEBAR SW-45.

The US$24 million project was officially inaugurated on February 25, 2019.?

|

| |

|

Park Avenue Tunnel, New York, USA |

|

The Park Ave Tunnel, owned and operated by the New York City Department of Transportation, is a vehicle tunnel that runs under Park Avenue in NYC from 33rd Street to 40th Street. It is 1,600 ft. long (488m) and passes under seven blocks of Park Avenue in Manhattan, NY. Originally constructed in the mid 1800's, it was in severe need of structural remediation. Wet process shotcrete was applied as a 9" (229mm) to 12" (305mm) internal shell along the entire vertical and overhead portions of the tunnel to create a structure that was much stronger than the original structure. Waterproofing, as well as strengthening, the tunnel was part of the scope of work.

The initial waterproofing design (a spray-applied polymer-modified, topical mortar) was replaced with a PAES (Penetron Admix Enhanced Shotcrete) solution. The proposal to use PAES was prepared by Tully Construction and Cruz Concrete, with performance testing provided by US Concrete Products and Penetron. After a thorough evaluation, PAES was approved after PENETRON ADMIX met all the specification criteria and did not interfere with the shotcrete placement characteristics or in-place properties.

Applying a waterproofing shotcrete layer (including PENETRON ADMIX) allowed for a faster construction schedule as it completely eliminated the need for the polymer-modified mortar application. Cruz Concrete applied approximately 3,000 cubic yards (2,294 m3) of PAES to reinforce the structure of Park Avenue Tunnel. The US$ 24.5 million project was completed in the 2nd half of 2019.

|

| |

|

|

|

| |

|